Alex is at the cutting edge of using this technology (a future employer will be very lucky) and I asked him to write up his specifications and thoughts on printing for the benefit of the 3D printing community. Here's what he has to say:

General Specifications

Hot end: 240 °C

Bed temp: 100 °C

Layer thickness: 0.2mm

Perimeters: 4 count

Infill type: Concentric

Speed

First layer print speed: 25mm/s

Print speed: 40mm/s

Travel speed: 125mm/s

Cooling Fan: off

Extrusion/Retraction

Extrusion multiplayer: 90%

First layer extrusion: 93%

Retraction length: 6mm

Retraction speed: 125mm/s

Adhesion

Dimafix

4 count brim

Glass plate

What I learned:

Adhesion and extrusion settings were the most important variables in printing. I had to apply more Dimafix around the corners of the print than the center and introduce a small brim to achieve proper layer adhesion through the print. I had to lower the Z offset (beyond what I would for PLA for ABS) to get better first layer adhesion. In following layers, I manually increased the Z offset just slight. If the nozzle was too far from the plate, the layer would not stick properly, however, if the Z offset was too low, the nozzle would grab material from the print as it extrudes. Improper adhesion would cause the corners of the print to curl and destroy the progress of the print. Applying too much Dimafix however, would make it close to impossible to remove from the bed.

Over-extrusion was a second variable adding to the debris build up around the nozzle. It was difficult at first to differentiate between the two. It will vary in printer type, but I narrowed ours down to the extrusion and retraction settings I had stated above. Decreasing the extrusion of the first layer however, made capturing the proper Z offset very important. Even with the successful print, I was still receiving a little over-extrusion and debris build up around the nozzle and had to pause the print to clean the nozzle. The debris did not build up over time, but rather varied based on contours and geometries at the specific stage of the print. The green part coming off the bed is unclean and needs to be sanded and filed to clean up the past troubles with extrusion.

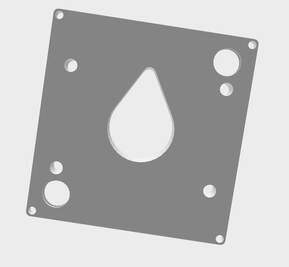

In terms of the material and how it physically printed, I would compare it to trying to print clay. Coming out of the hot end, it does not stick to the bed as you would expect. Rather, it sticks to itself at times you don’t want it to and doesn’t when you do. Geometrically the material is very limited. Holes below a 10mm radius print unclean and inconsistent through layers. Thicker walls the better. Any internal fillets or contours are difficult and should be avoided. The optimal print for this material would be a gear or some small, geometrically uncomplex, internally uniform object.

Alex's work was supported by a grant from the Center for Undergraduate Excellence at Chapman University.

RSS Feed

RSS Feed